-

Quick Links:

-

Filtration Terms and Definitions

-

Filter Efficiency and Beta Ratio Curve

-

What is Right For You? Bag Filter or Cartridge?

-

Design Considerations, Employing TSS and PSD Data

-

Absolute vs. Nominal Rated Filters

-

Reverse Osmosis Pre-Filtration Issues

-

Particle Size and Technology Employed

-

Example Applications of M/F, U/F, and N/F Membranes

-

Viscosity of Common Liquids

-

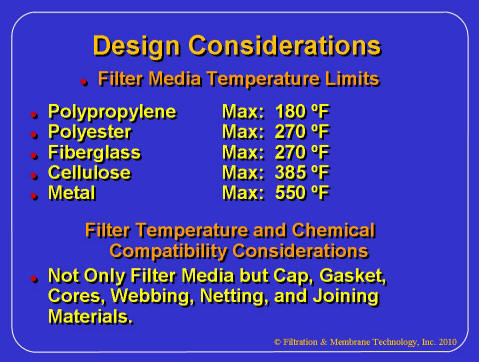

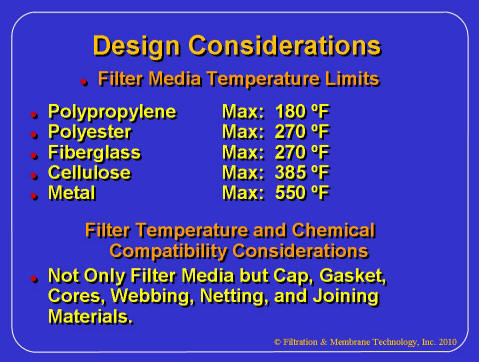

Temperature Limits for Filter Media

-

O-Ring Technical Data

-

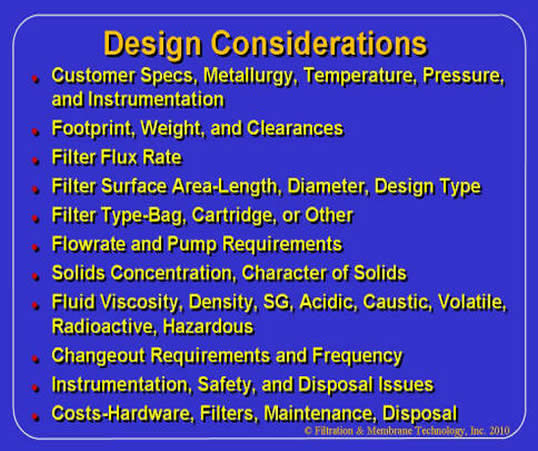

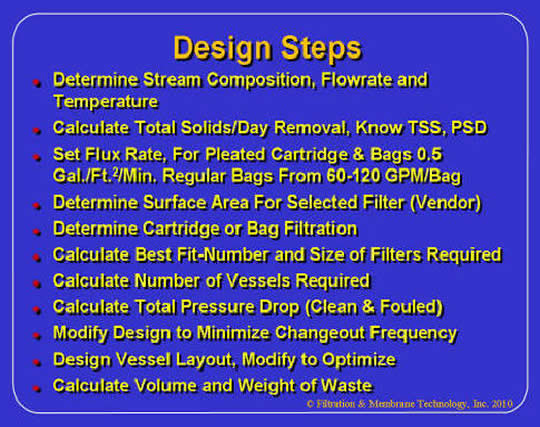

Overall Filtration System Design Considerations

Filtration Terms and Definitions:

Absolute Rating |

Diameter of the largest particle normally expressed in micrometers, which will pass through the filter. This loosely represents the pore size of the filter. A totally uniform filter media, each with exactly the same size hole or pore size theoretically has an exact absolute rating. Rating tests often use ISO Fine Test Dust, spherical identical glass beads or a mixture of glass beads and carbonyl iron. |

Nominal Filtration Rating |

An arbitrary value determined by manufacturer and expressed in terms of percentage retention (normally 90%, 95% or 98% by weight of a specified contaminant (Le. glass beads), of given size. |

Beta Ratio |

The ratio of the number of upstream particles larger than a specific size to the number of downstream particles larger than a specified size |

Vessel Blowdown |

The use of pressure to remove liquids and/or solids from a vessel to change filters |

Burst Strength |

The ability of a filter medium such as a filter paper to resist disruption by pressure applied in a direction normal to the surface. |

Dirt Holding Capacity |

The quantity of contaminant that a filter element is capable of retaining without exceeding a specified differential pressure at rated flow. |

Collapse Pressure |

The minimum differential pressure that a filter element is designed to withstand without permanent deformation |

Contaminant Capacity |

The resultant weight of a contaminant (usually ISO fine test dust) which when added at specified intervals and at a specific low rate produces a differential pressure across a filter element which can be converted or related to useful life of a filter element. |

Filtration |

A measure of the efficiency of filter element expressed in terms of percentage retention of standard contaminants under defined test conditions (Nominal Rating); and the size in microns of the largest hard spherical particle that will pass through the filter element (Absolute Rating) |

Depth Filtration |

Fluid flowing through a mass filter media following a tortuous path with many entrapments. |

Disposal Filter Element |

A filter element, which is not cleanable and is therefore discarded and replaced at the end of its useful life. (Sometimes referred to as throwaway or non-cleanable element.) |

Effective Filtration Area |

That area of the fluid medium in a filter element which is exposed to flow. The ability of a filter element to remove/retain a specific artificial contaminant in a specified concentration under controlled test conditions. Efficiency is expressed in percent for various micron sizes. |

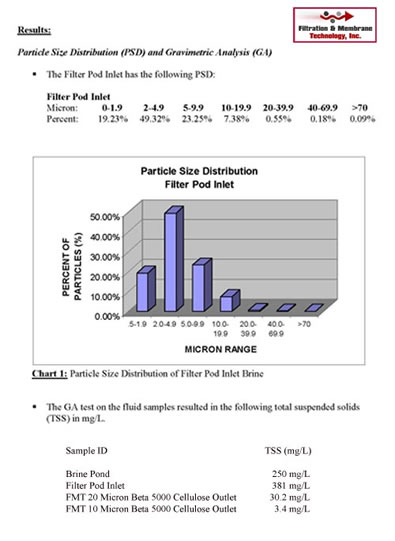

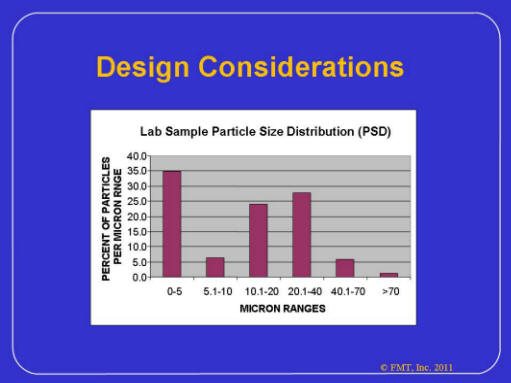

Particle Size Distribution (PSD) |

The distribution obtained from a particle count grouped by specific micron sizes. |

Total Suspended Solids (TSS) |

The TSS of a liquid sample is determined by filtering a known volume in liters through a pre-weighed filter. The residue retained on the filter is dried in an oven at 103 to 105° C until the weight of the filter no longer changes. The increase in weight of the filter represents the total suspended solids in mg/l. |

Viscosity Correction |

Flow rates through filters are reduced as the viscosity increases >Correction Factor Varies by Filter Type, Micron Rating and DesignVessels and inlet/outlet pipe size also have viscosity and flow correction factors. Charts and calculations are available from manufacturers guide manuals and their web sites. |

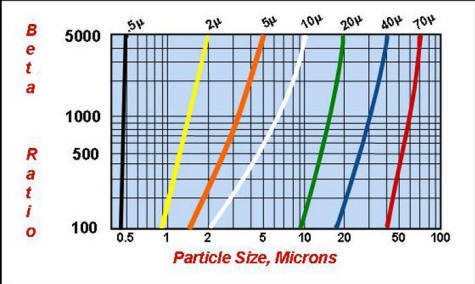

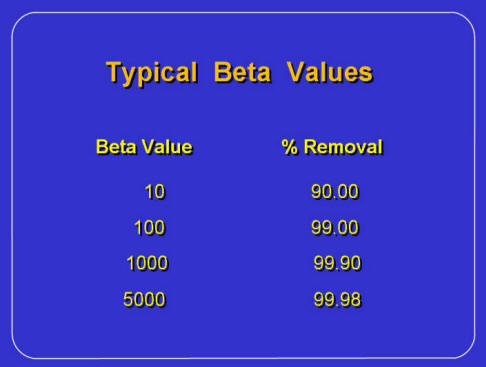

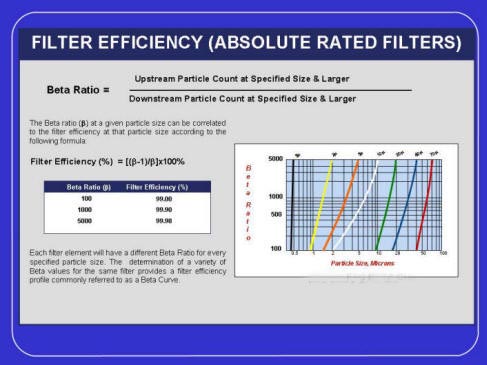

Filter Efficiency(%) and Beta Ratio Curve:

Filter selection is specifically tied to the particulate removal efficiency factor known as the Beta Ratio. The engineer usually sees absolute rated filter efficiencies listed as 99%, 99.9% or 99.98%.

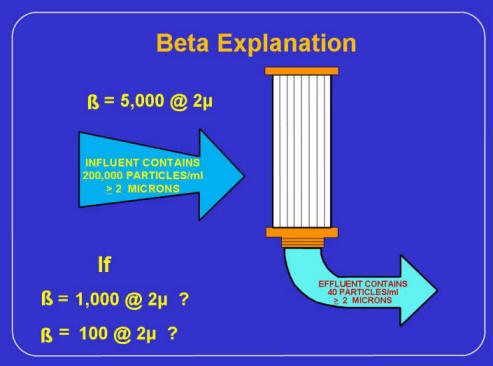

The tried and true use of efficiency as a % is difficult to understand and explain to purchasing or management who wants to know why a 99.98% efficiency filter may be significantly higher in price than a 99% filter. A simple calculation called the beta ratio is much easier to understand (and explain) and can eliminate a host of uncertainties which become extremely significant when a critical process and equipment such as RO systems are concerned. Just what is the difference between a filter rated at 99% efficiency to one at 99.9% or greater?

For example: We start with a 99.98% absolute rated efficiency filter at 2 microns. What is the real world difference if the filter efficiency is 99% or 99.98% at 2 microns? If we do the simple calculation (See Figures Below), we see that 99.98% efficiency equates to a beta ratio of 5,000. A 99% efficiency filter has a beta ratio of 100. The engineer can now describe the differences in filters in easy to understand terms: a beta 5,000 filter will only pass 1 particle in 5,000 greater than 2 microns. A beta 100 filter will pass 1 in 100 particles greater than 2 microns. So, while efficiency rated in % is typically what is published in literature or data sheets, it does not really describe what is happening as beta ratios do. Understanding Beta Ratio is critical to understand and explain filter efficiency.

How Do You Interpret This Log-Log Graph?

Examine the Explanation

This is valid only for Absolute Rated filters, Not Nominal Rated filters

Back To Top

What Filter Type is Right For You, Bag, Cartridge, Other?

How do YOU Decide if a Bag or Cartridge Filter and the Vessel Type are the Best Choice for your Separation Problem?

1) Please Review this Technical Article Published in Chemical Engineering Magazine

2) Rank Your Filtration Parameters In Order of Importance To You: System Flow Rate Capability, Final Product TSS and PSD, Vessel(s) Footprint and/or Vessel(s) Weight, Changeout Frequency, or Decontamination Required?

FMT Supplies Solutions to Particulate and Hydrocarbon Contamination of Influent To Protect Your Membranes, Molecular Sieve Resin Beds, Heat Exchangers, Coalescers, and Instrument Probes.

Absolute Rated Bag and Cartridge Filters are Available at a Beta Ratio of 5000 to 100(99.98% to 99%) Efficiency.

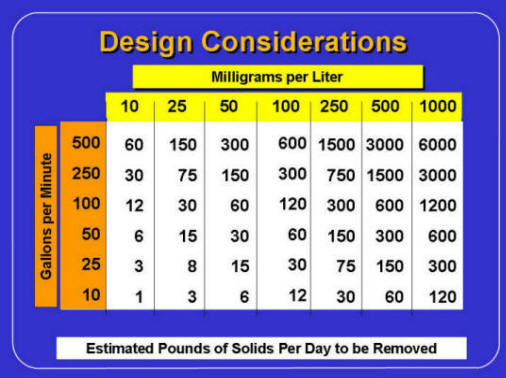

Design Considerations, Particle Size Distributions and Total Suspended Solids

The Table on the left of TSS in mg/l vs. flow in GPM is employed to estimate the Solids Entering a Filter and Solids the Filter did not Remove. The Table on the right displays a lab sample PSD that is employed to determine the optimum filter's micron rating. The final truth is a full flow test of the selected filter in the plant environment employing the true fluid and true solids.

Several Filters are teste to determine optimum results

employing TSS & PSD Gravimetric Test results.

Absolute Rated Filters vs. Nominal Rated

The design engineer will be confronted with the question of nominally rated filters and absolute rated filters. Most nominal rated filters are found in single layer bag filters and cartridge filters employing coiled string or media that does not have a uniform pore size, a large average pore size, or the media that can move during filtration (not-fixed in location by binders or of uniform pore size). So it’s efficiency rating is not uniform from filter to filter or within the same filter and/or is low in the ability to reproduce uniform tests of efficiency and must be averaged to report a result.

uniform pore size, a large average pore size, or the media that can move during filtration (not-fixed in location by binders or of uniform pore size). So it’s efficiency rating is not uniform from filter to filter or within the same filter and/or is low in the ability to reproduce uniform tests of efficiency and must be averaged to report a result.

Nominal rated filters are used extensively in water and wastewater treatment applications. Figures below indicates the relative dirt holding capacities of nominal and absolute rated bag and cartridge filters. A nominal filter cannot have a beta ratio rating

because the tests of nominal rated filters are not reproducible under tests that include changes in flow rate and pressure

including pressure surges that can move the media or dislodge bridged prticles that changes the actual pore size.

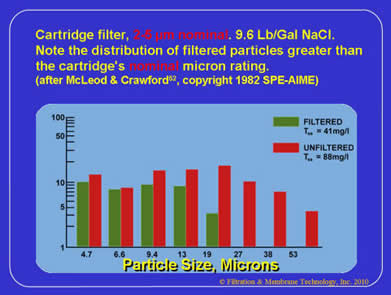

There are attempts to relate a nominal rated filter to an absolute but the designs and materials of construction of the two different ratings do not allow a true comparison. If you examine Figures below, you will notice that even though a nominal filter is rated at 5 microns, reductions in filtered vs. unfiltered do not become significant until after 19 microns.

Back To Top

Reverse Osmosis Pre-Filtration Issues

Reverse Osmosis (RO) systems are used for boiler feed water treatment and a host of pharmaceutical, municipal, and other industrial applications. The membrane RO systems are sensitive to contaminants and usually have a pre-filter to protect them. However, the pre-filter is usually designed as an afterthought instead of as the critical protection device it actually is. Pretreatment can include more than just absolute filtration including separation processes such as sedimentation, flotation, granular media, pre-coat filters (DE filters) and screening. Pretreatment problems may include hydrocarbons, Cryptosporidium & Giardia, fresh & seawater mussels, and mollusks in their various life forms.

Particle Size and Technology Employed

Inlet water quality is a moving target, constantly changing and subject to major changes such as construction projects upstream or runoff changes, dredging operations, requirements to totally change feed sources due to aquifer or drought issues. Large surface area filters now exist with small footprints where the efficiency and changes in water source quality can be handled best if considered in the design stage. (See: Industry challenges in water pre-filtration-AFS 2008).

Filters used in refineries and petrochemical plants handle very large volumes of product or processing fluids on a continuous basis. Other plant operations are batch found throughout the process industries. Regardless of whether the process is  batch or continuous, on-line time is extremely critical to optimize profitability. Shutting down due to a filtration problem (or any problem) affects bottom line production income by as much as $10,000 per hour or more. Batch operations have more flexibility, but the choice of the filter, its efficiency to perform the required task, and its dirt holding capacity is also a major concern. Potential product sitting in holding tanks that cannot be shipped because the filtrate does not meet Quality Control Specifications can halt production just as in a continuous process.

batch or continuous, on-line time is extremely critical to optimize profitability. Shutting down due to a filtration problem (or any problem) affects bottom line production income by as much as $10,000 per hour or more. Batch operations have more flexibility, but the choice of the filter, its efficiency to perform the required task, and its dirt holding capacity is also a major concern. Potential product sitting in holding tanks that cannot be shipped because the filtrate does not meet Quality Control Specifications can halt production just as in a continuous process.

Examples of MF, UF, and NF Membrane Applications

Examples of MF Applications |

|||

Application |

Permeate |

Concentrate(Retentate) |

Benefits of MF |

Cranberry juice clarification |

Low turbidity, clear juice |

Juice, suspended solids, colloidal haze particles. |

Removes suspended solids and turbidity while allowing the passage of color, sugar and taste. |

Wine filtration |

Low turbidity, clear, flavorful wine |

Wine, suspended solids, colloidal haze particles. |

Removes suspended solids and turbidity while allowing the passage of color, alcohol and taste. |

Industrial Waste Water Treatment |

Water & dissolved solids |

Water, suspended solids, insoluble metal hydroxide solids. |

Removes suspended solids and insoluble metal hydroxide solids from wastewater to allow the permeate to be discharged to a local POTW. |

Fermentation broth clarification |

Water & dissolved solids |

Water & suspended solids |

Removes suspended solids from the fermentation broth leaving clarified liquid. |

Examples of UF Applications

Examples of UF Applications

|

|||

Application |

Permeate |

Concentrate (Retentate) |

Benefits of UF |

Potable Water |

Potable water free of suspended solids, turbidity, bacteria and large viruses |

Water, particulate solids |

Certified for 4-log removal of bacteria, giardia, cryptosporidium and viruses from drinking water. |

Oily Wastewater |

Oil free (< 50 mg/L) water |

Water, suspended solids, insoluble metal hydroxides, etc. |

Consistent permeate water quality even when feed composition subject to upsets. Highly concentrated oil emulsion for waste disposal. |

Paint |

Water, dissolved salts and solvents |

Water, paint resins and pigments |

Allows the recovery of valuable paint resins and pigments. |

Milk |

Lactose and salts solution |

Protein concentrate |

Protein concentration at lower energy cost than evaporation. |

Whey |

Lactose and salts solution |

Whey Protein Concentrate (WPC) |

Protein concentration at lower energy cost than evaporation. |

Apple juice clarification |

Low turbidity, clear juice |

Juice, suspended solids, pulp, colloidal haze particles. |

Removes suspended solids and turbidity while allowing the passage of juice, sugar and taste. |

Reuse of municipal wastewater |

Water free of suspended solids, bacteria & viruses |

Water, particulate solids |

Polishes biologically treated municipal effluent for discharge, reuse, or feed to reverse osmosis |

Industrial MBR, e.g. malting industry |

Water Containing*: |

Malting wastewater, activated sludge |

Meets stringent effluent discharge requirements, eliminates solids, reduces wastewater discharge fees, and requires less space than conventional wastewater treatment |

Examples of NF Filtration Applications

Application |

Permeate |

Concentrate |

Benefits of NF |

Whey / Whey Permeate |

Salty wastewater |

Desalted whey concentrate |

Allows the recovery of lactose and whey protein concentrate with reduced salt content |

Textile |

Dyes |

Water, salts, BOD, COD and color |

NF is used to desalt dyes resulting in a higher value product |

Caustic cleaning solutions |

Caustic cleaning solution |

BOD, COD, suspended solids, caustic cleaner |

Allows caustic cleaning solution to be recycled resulting in reduced cleaning chemical costs |

Recycle of acid solutions |

Acid solution |

BOD, COD, calcium, suspended solids, acidic water |

Allows acid solution to be recycled resulting in reduced cleaning chemical costs |

Water |

Softened water |

Hard water |

Potable water production. Softened water reduces scaling on equipment and heat exchange surfaces |

Antibiotics |

Salty waste product |

Desalted, concentrated Antibiotics |

NF produces high value pharmaceutical products |

Back To Top

Viscosity of Common Filtered Liquids

Contact FMT For Viscosity Flow Corrections

Temperature Limits For Common Filter Media

Back To Top

O-Ring/Gasket Technical Data

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Impermeability |

Fair |

Good |

Poor |

Excellent |

Good |

Tensile Strength |

Good |

Good |

Poor |

Excellent |

Good |

Kalrez® and Viton® are registered trademarks of E. I. DuPont de Nemours

General Filtration System Design Considerations

Back To Top

Filtration & Membrane Technology, Inc.•370 Camden Hills W., Montgomery, TX, 77356•Phone: 713-870-1120

E-Mail fmt-houston@att.net