Filters

Pleated Liquid Filter Specifications and Data Sheets:

Manufactured in the USA with FDA Approved Materials.

Pleated Cartridge Filters:

Conventional DOE and 222 End Cap Stick Cartridge Series Filters 99-99.98% Efficiency (Beta Ratio 100-5000) Holds up to 2# Dirt. These filters have an OD of 2.5", 3", and 3.75" x various lengths.

336 Series Pleated Cartridge Filters 99-99.98% Efficiency (Beta Ratio 100-5000) Holds up to 2.5# Dirt. These filters have an OD of 3" x 36" long.

Platinum 740 Series 226 End Cap Filters (Improved 3MTM 740B Design) 99-99.98% Efficiency (Beta Ratio 100-5000) Holds up to 20# Dirt. These filters are 6.25" OD x various lengths. NSF version available.

Deep Pleat 740 Cartridge 226 End Cap Series Filters 99% Efficiency (Beta Ratio 100) Holds up

to 18# Dirt. These filters are 6.25" OD x various lengths.

Platinum 940 High Surface Area 235 End Cap Series Filters 99.98% Efficiency (Beta Ratio 5000) Holds up to 100# Dirt. These filters are 12.75" OD x various lengths.

Platinum 2040 High Surface Area 235 End Cap Series Filters 99.98% Efficiency (Beta Ratio 5000) Holds up to 300# Dirt. These filters are 20" OD x various lengths.

Gas Filter Series to Protect Coalescers, Compressors, Gas Turbines, Burners, Fuel Gas Systems

FMT Pipeline Pigging Filters Gas and Liquid Filters from 0.3-100 Micron up to 90" Long. Looks like a Cartridge Filter But Flow Is Inside to Outside.

FMT supplies cartridge filters 10" to 80" long with diameters from 2" to 20". Filters are custom built with most common sizes in stock ready for shipment worldwide. Do you require high temperature materials or do you need to reduce filters change outs because of hazardous chemical exposure? Are you paying too much for name brands filters but require the same quality?

![]()

Pleated Bag Filters:

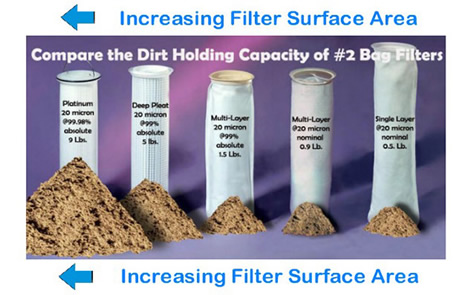

Pleated Nominal Series Bag Filters Up to 28 Times the Solids Holding of Multilayer Bags

High Capacity 550 Series Bag Filters Pleated Bag Filters 99% Efficiency (Beta Ratio 100) Holds up to 5# Dirt

Maximum Capacity 650 Series Bag Filters Pleated Bag Filters 99.98% Efficiency (Beta Ratio 5000) Holds up to 24# Dirt

HI-FLOW Bag FMT DPU-600 Series Bag Filters 99.98% Efficiency (Beta Ratio 5000) Flows up To 500 GPM Per Filter. Filters are 6" OD x 3" ID in Various Lengths and Configurations.

FMT Pipeline Pigging Filters Gas and Liquid Filters from 0.3-100 Micron up to 90" Long. Looks like a Cartridge Filter But Flow Is Inside to Outside.

Pleated Bag Filters are designed to fit the following vessels: Rosedale, FSI, 3M, GAF, Knight, Fulflo, Barron, Fil-Trek, FTC, Fulflow, RP, Pleasant, Hayward, Champion Process, Pall, Parker, and Nowata. Upgrade and obtain over 10 times the solids holding capacity. Don't see your bag filter vessel, we will build a filter for you.

Bag Filter Vessel To Cartridge Filter Vessel Conversions

You can convert your bag filter vessel to cartridge filter style with a series of Max-Out Cartridge Filters that are available designed specially for the Max-Out basket. Flow is into the top of Max-Out basket. A flow channel exists between the basket and filter. Flow is into filter and out the center discharge.

Why do this? The Max-Out System allows for high temperature and special medias including metal can body designs that which may be required but most importantly-much higher solids holding (20-40 times) standard bag filter solids holding capacities.

![]()

3M®/CUNO® and PallTM Series Replacement Filters:

3MTM/CUNO® HF High Flow Filter Series Retrofits

Replaces Radial Pleat HF Series (0.5µ-135µ) (HF40PP005C01) (HF60PP005C01)

3MTM/CUNO® 520 Series Bag Filter Retrofits

Replace 500 Series 1000 In-Stock Each Micron Size (Model 522-529, 2.5µ-48µ)

3MTM/CUNO® 740 Series Cartridge Filter Retrofits

Replace 740B 1000 In-Stock Each Micron Size (Model 742-749, 1µ-70µ)

3MTM/CUNO® High Flow Series Retrofits Replace Radial Pleat High Flow

Pall MarksmanTM PFT, DFN, XLD Retrofits Pleated Bag Filters

Pall MarksmanTM 740 Series Cartridge Filter Retrofits 1000 In-Stock of Each Micron Size

Pall MarksmanTM Ultipleat High-Flow Series Bag Filter Retrofits

Pall MarksmanTM MCC1401 Pleated Cartridge Filter Retrofits

FMT has been retrofitting 3M® and PallTM bag and cartridge filters for over 25 years.

![]()

Ronningen Petter (R-P), (RP) Series Cartridge and Bag Filters

Max-Load series RP-720A and C; 740B, D and E Filters for RP 740-D, 740-B, 720-A, 720-C, 720-E, 940-D Vessels

Max-Load series RP-720A and C; 740B, D and E Filters (Contact FMT for Help with Vessel Type and Filter Codes)

RP vessels and filters were manufactured by Eaton Corporation. The vessels and pleated filter series were discontinued. RP vessels currently in service can be supplied by FMT with high capacity filters for both inside-out and outside-in flow designs.

Ceramic Filters

FMT offers two types of ceramic membrane filtration systems, Ceramem® and Kleansep™

CeraMem® Ceramic Membrane Filters For Industrial Applications:

This product line of membrane filters and modules are large-diameter monolithic ceramic elements composed mainly of Silicon Carbide. CeraMem membrane filters have provided a robust solution for water and waste water treatment needs across a variety of industries for over 30 years. Used either in dead- end or in crossflow operation, CeraMem membrane filters offer a large membrane area in a compact footprint compatible with a wide range of conditions. Ceramem was acquired by Alsys from Veolia in 2017.

Filtration pore sizes to .005 microns (5 nm) are available. This product line covers the MF Microfiltration (0.1 -10 micron) and UF Ultrafiltration (0.005-0.1 micron). In cross-flow filtration mode these systems offer the user a continuous self-cleaning filtration system.

Learn More About Ceramic Membranes And Why They Are Useful For Industrial Applications

CeraMem® Skidded Systems Data Sheet

Oil & Gas, Refining and Petrochemical

-

Produced water: steam flood, water flood, surface discharge, reinjection, reuse

-

Completion fluid filtration

-

Sulfuric Acid filtration for reuse

-

Workover fluid filtration

-

Disposal well reinjection

-

Desalter brine

-

FPSO slop water

-

EOR fluids

-

Oil filtration for oil recovery

-

Solvent Deasphalting

-

Vacuum Residual Oil Recovery

Chemical Process Industry

-

Sodium bicarbonate brine filtration

-

Chlor-alkali brine filtration

-

Membrane biological reactors (MBR)

-

Acid filtration for recycle/reuse

-

Caustic filtration for recycle/reuse

-

Oil filtration

Environmental

-

Oily Wastewater Treatment

Primary Metals Industry and Metal Finishing

-

Heavy metals removal

-

Oil & grease removal

-

Dewater spent water soluble coolants and rolling oils

-

Caustic cleaner and degreaser recycle

-

Oil filtration for recovery

Marine industry

-

Bilge water filtration

Mining industry

-

Tailings pond filtration

Pulp and paper industry

-

Black liquor

Disaster relief

-

Emergency drinking water

Kleansep™ Ceramic Membrane Filters For Food and Pharmaceutical Applications:

The Kleansep product line of membrane filters and modules employ FDA approved materials and are employed for treatment of industrial and domestic waste water, production of chemicals, pharmaceuticals, including treatment of animal feed and human food ingredients. Membrane elements are composed of ZrO2, TiO2, or Al2O3.

Microfiltration elements are (0.1 -10 micron), UF Ultrafiltration (8kD-300kD), Nanofiltration (1kD-5kD). Kilodaltons kD or KDa are approximately equal to molecular weight.

Food and beverage industry

-

Fermentation broth clarification

-

Wine filtration

-

Beer filtration

-

Recovery of valuable components from food waste

-

Membrane biological reactors

-

Caustic cleaner recovery

-

Natural spring water

Biotechnology industry

-

Fermentation broth clarification

Nuclear power industry

-

Wastewater

Skidded pilot units and lab testing are available.

![]()

Chlor-Alkali Brine Polishing Filter Systems

Filter Systems for Brine Applications

Whole House Water Filtration System

Rated: 100,000 Gallons/Month for 12 Months

Whole House Water Filter Systems

Wastewater/Produced Water

Dual Particulate And Hydrocarbon Removal Systems-Onshore/Offshore

Systems From 15-315 GPM

Link To Rental Vessels Page

Further Information? Please Call or E-mail Us